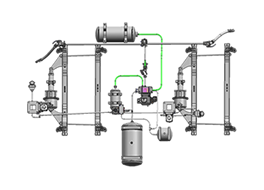

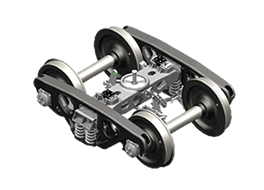

Railway Axles are key components of railway rolling stock. Together with wheel, bearing, axle box, brake disc and gear system, can be assembled to be wheel set system for railway bogie. The axles serve to transmit driving torque to the wheel, as well as to maintain the position of the wheels relative to each other and to the vehicle body.

According to railway vehicles, the axles can be grouped as freight wagon axle, coach axle, and locomotive axle.

TEDRAIL can supply almost all types of axles according to the main specification worldwide. Such as:

TB/T 2945 Specifications of Steel LZ50 Axle and Billet for Rolling Stock, CHINA RAILWAY

AAR M-101 Axles, Carbon Steel, Heat-Treated, AMERICAN ASSOCIATION RAILWAY

UIC 811-1 Technical Specification for The Supply of Axles for tractive and Trailing Stock, INTERNATIONAL UNION OF RAILWAYS

BS 5892-1 Specification for Axles for Traction and Trailing Stock, BRITISH STANDARD

EN 13261 Railway applications – Wheelsets and Bogies-Axles-Product Requirements, EUROPEAN STANDARD

JIS E4502 Axles for Railway Rolling Stock – Quality Requirements, JAPANESE INDUSTRIAL STANDARD

IRS 16/95 Indian Railway Standard Specification for Steel Axles for Carriages and Wagons, INDIAN RAILWAY

There are various kinds of railway axle material could be chose according to customer’s requirements. Normally TEDRAIL could offer following materials:

| MATERIAL | STANDARD | CHEMICAL COMPOSITION | |||||||||

| C | Mn | Si | P | S | Cr | Ni | Mo | Cu | V | ||

| EA1N | EN13261 | ≤0.4 | ≤ 1.2 | ≤ 0.5 | ≤0.02 | ≤0.02 | ≤0.30 | ≤0.30 | ≤ 0.08 | ≤ 0.30 | ≤ 0.06 |

| EA1T | |||||||||||

| EA4T | EN13261 | 0.22-0.29 | 0.5-0.8 | 0.15-0.4 | ≤0.02 | ≤0.015 | 0.9-1.2 | ≤0.30 | 0.15-0.3 | ≤ 0.30 | ≤ 0.06 |

| A1N | BS5892-1 | ≤0.4 | ≤ 1.2 | ≤ 0.5 | ≤0.04 | ≤0.04 | ≤0.30 | ≤0.30 | ≤ 0.08 | ≤ 0.30 | ≤ 0.05 |

| A1T | |||||||||||

| A2N | BS5892-1 | ≤0.5 | ≤ 1.2 | ≤ 0.5 | ≤0.04 | ≤0.04 | ≤0.30 | ≤0.30 | ≤ 0.08 | ≤ 0.30 | ≤ 0.05 |

| A2T | |||||||||||

| A3T | BS5892-1 | ≤0.4 | ≤ 1.6 | ≤ 0.5 | ≤0.04 | ≤0.04 | ≤0.5 | ≤0.30 | ≤ 0.40 | ≤ 0.30 | ≤ 0.1 |

| A4T | BS5892-1 | ≤0.3 | ≤ 0.8 | ≤ 0.5 | ≤0.04 | ≤0.04 | ≤1.2 | ≤0.30 | ≤ 0.35 | ≤ 0.30 | ≤ 0.1 |

| A1(N) | UIC811-1 | ≤0.37 | ≤ 1.12 | ≤ 0.46 | ≤0.04 | ≤0.04 | ≤0.30 | ≤0.30 | ≤ 0.05 | ≤ 0.30 | ≤ 0.05 |

| A1(T) | |||||||||||

| A2(T) | UIC811-1 | 0.17-0.27 | 1-1.4 | ≤ 0.4 | ≤0.025 | ≤0.03 | 0.2-0.7 | ≤0.30 | ≤ 0.15 | ≤ 0.25 | 0.05-0.15 |

| A3N) | UIC811-1 | 0.42-0.5 | 0.5-0.8 | 0.15-0.4 | ≤0.035 | ≤0.035 | ≤0.30 | ≤0.30 | ≤ 0.08 | ≤ 0.30 | ≤ 0.05 |

| A3(T) | |||||||||||

| A4(T) | UIC811-1 | 0.22-0.29 | 0.5-0.8 | 0.15-0.4 | ≤0.035 | ≤0.035 | 0.9-1.2 | ≤0.30 | 0.15-0.3 | ≤ 0.30 | ≤ 0.05 |

| A5(T) | UIC811-1 | ≤0.45 | ≤0.9 | ≤ 0.4 | ≤0.035 | ≤0.035 | ≤1.2 | ≤0.30 | ≤ 0.30 | ≤ 0.30 | ≤ 0.10 |

| Grade F | AAR M-101 | 0.45-0.59 | 0.7-1 | 0.15-0.4 | ≤0.045 | ≤0.05 | 0.02-0.08 | ||||

| N | IRS:R-16/95 | ≤0.37 | ≤1.12 | 0.15-0.46 | ≤0.04 | ≤ 0.04 | ≤ 0.30 | ≤ 0.30 | ≤0.05 | ≤ 0.30 | ≤ 0.05 |

| T | |||||||||||

| LZ50 | TB/T 2945 | 0.47-0.57 | 0.6-0.9 | 0.17-0.40 | ≤ 0.03 | ≤ 0.03 | ≤ 0.30 | ≤0.30 | ≤ 0.25 | ||

| SFA60A | JIS E 4502-1 | ≤0.035 | ≤0.04 | ||||||||

| SFA60B | JIS E 4502-1 | ≤0.045 | ≤0.045 | ||||||||

| MATERIAL | STANDARD | Heat Treatment (N/T) | MECHANICAL PROPERTIES | AREA | ||||

| ReH N/mm2 | Rm N/mm2 | As% | KU LONGITUDINAL(J) | KU TRANSVERSE(J) | ||||

| EA1N | EN13261 | N | ≥ 320 | 550 - 650 | ≥22 | ≥30 | ≥25 | EUROPEAN,IRAN |

| EA1T | T | ≥ 350 | 550 -700 | ≥24 | ≥40 | ≥20 | ||

| EA4T | EN13261 | T | ≥ 420 | 650 - 800 | ≥18 | ≥50 | ≥25 | |

| A1N | BS5892-1 | N | ≥ 300 | 520 - 650 | ≥22 | ≥25 | ||

| A1T | T | ≥ 350 | 550 - 700 | ≥24 | ≥40 | |||

| A2N | BS5892-1 | N | ≥ 360 | 600 - 750 | ≥17 | ≥20 | ||

| A2T | T | ≥ 390 | 620 - 770 | ≥19 | ≥25 | |||

| A3T | BS5892-1 | T | ≥ 420 | 650 - 800 | ≥19 | ≥40 | ||

| A4T | BS5892-1 | T | ≥ 420 | 650 - 800 | ≥19 | ≥40 | ||

| A1(N) | UIC811-1 | N | ≥ 320 | 550 - 650 | ≥22 | ≥25 | ≥10 | |

| A1(T) | T | ≥ 350 | 550 - 700 | ≥24 | ≥40 | ≥15 | ||

| A2(T) | UIC811-1 | T | ≥ 350 | 510 - 620 | ≥22 | ≥40 | ≥20 | |

| A3N) | UIC811-1 | N | ≥ 360 | 600 - 750 | ≥17 | ≥20 | ≥10 | |

| A3(T) | T | ≥ 390 | 620 - 770 | ≥19 | ≥25 | ≥13 | ||

| A4(T) | UIC811-1 | T | ≥ 420 | 650 - 800 | ≥18 | ≥40 | ≥20 | |

| A5(T) | UIC811-1 | T | ≥ 510 | 730 - 880 | ≥14 | ≥25 | ≥13 | |

| Grade F | AAR M-101 | N | ≥345 | ≥ 607 | ≥22 | USA/CANADA/MEXICO | ||

| N | IRS:R-16/95 | N | ≥320 | 550 - 650 | ≥22 | ≥25 | INDIA | |

| T | T | ≥350 | 550 - 700 | ≥24 | ≥40 | |||

| LZ50 | TB/T 2945 | N | ≥ 345 | ≥ 610 | ≥19 | CHINA | ||

| SFA60A | JIS E 4502-1 | N | ≥295 | ≥590 | ≥20 | ≥31 | JAPAN | |

| SFA60B | JIS E 4502-1 | N | ≥295 | ≥590 | ≥20 | ≥31 | ||

AAR STANDARD SOLID AXLES

TEDRAIL supply the standard axles which fully comply with AAR M-101 Specification as following features:

Class D, E, F, G, & K.

Material: AAR M-101 Grade F

Meter gauge, Standard gauge and Broad gauge.

Test Certificate: Chemical Composition Test, Tensile Strength Test, Ultrasonic Inspection, Magnetic Inspection, Surface and Dimensions

Rough Axle, Semi-Finished Axle, Finished Axle

Freight Wagon Axle, Coach Axle, Locomotive Axle

| Type | Journal size | Size | Weight | Axle load | Material | |||||

| C | D | I | K | 0 | W | |||||

| Class D | 5 1/2x10 | 1 3/4" | 7 5/8" | 7 9/16" | 5 7/8" | 86 1/8" | 10 1/6" | 393kg | 16.4t | AAR CLASS F |

| Class E | 6x11 | 1 13/16" | 7 5/8" | 8 1/4" | 5 7/16" | 88" | 10 15/16" | 442kg | 20.5t | |

| Class F | 6 1/2x12 | 1 13/16" | 7 5/8" | 8 3/4" | 7 3/8" | 89 5/8" | 11 3/4" | 533kg | 24.5t | |

| Class G | 7x12 | 2 5/16" | 7 5/8" | 9 1/2" | 8" | 89 1/4" | 11 1/16" | 609kg | 35.7t | |

| Class K | 6 1/2x9 | 3.397" | 7 5/8" | 8 3/4" | 7 3/8" | 87.156" | 8.931" | 523kg | 32.4t | |

| Class L | 6x8 | 3.293" | 7 5/8" | 8 1/4" | 6 7/16" | 85.5" | 8.207" | 415kg | 20.5t | |

| Class M | 7x9 | 3.5" | 7 5/8" | 9 1/2" | 8" | 87.5" | 9" | 593kg | 35.7t | |

EUROPEAN STANDARD SOLID AXLES

TEDRAIL supply the standard axles which fully comply with European Specification as following features:

Standard: EN13261/UIC 811-1/BS 5892 PART1

Material: EA1N/EA4T

Meter Gauge, Standard Gauge, Broad Gauge

Test Certificate: Chemical Composition Test, Tensile Strength Test, Impact Test, Ultrasonic Inspection, Magnetic Inspection, Surface and Dimensions

Fatigue Characteristics, Residual Stresses

Rough Axle, Semi-Finished Axle, Finished Axle

Freight Wagon Axle, Coach Axle, Locomotive Axle

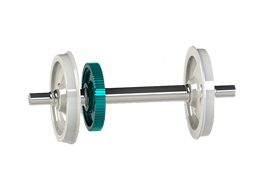

HOLLOW AXLE

TEDRAIL supply the standard axles which fully comply with European Specification as following features:

The hollow axle is one of the key components of the high-speed coach. The hollow axle mainly used for high-speed power train. The advantage of hollow axle is the quality of light.

TEDRAIL can supply various kinds of finished and semi-finished Hollow axle for railway rolling stocks.

Hollow axle could be manufactured in accordance with EN 13261, AAR M-101, IRS 16/95, JIS E 4502, TB/T 2945 and BS 5892-1.

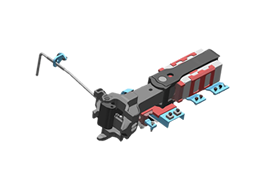

POWER TRAIN AXLE

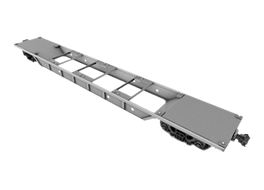

TRAIL AXLE