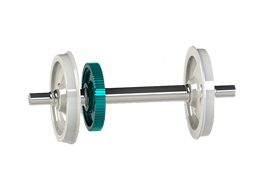

Railway Wheel center has been pressed together with wheel tyre and Gibson ring to be tyred wheel. The hub is assembled with railway axle, and functioned as wheelset. According to different specification, the wheel centre can be manufactured by

Casting

Forged or Rolled

MANUFACTURING SPECIFICATIONS:

FORGED, ROLLED WHEEL CENTRE

From European standard, the wheel center has to be forged and rolled. TEDRAIL can deliver the forged wheel centre as following related specifications:

BRITISH STANDARD: BS 5892 PART 2, Railway rolling stock materials –Part 2. Specification for forged and rolled wheel centres

EUROPEAN STANDARD: UIC 812-1Technical specification for the supply of forged or rolled wheel centres for tyred wheels for tractive and trailing stock; Quality prescriptions.

ISO 1005-4 Railway rolling stock material – Part 4: Rolled or forged wheel centres for tyred wheels for tractive and trailing stock-Quality requirements.

Features:

- Machining: Wheel center should be full machined according to the product drawing includes hub, rim, web and etc.

- Material: strictly matching the specification.

- Test Certificate: Chemical Analysis, Tensile Test, Dimension and Surface Finish provided according to the specification. NDT- Ultrasonic and Magnetic Inspection could be done per customer request.

- Heat Treatment Delivery Status: U-untreated and N-Normalized or Normalized and Tempered.

CASTING WHEEL CENTRE

However, except the forged wheel center, according to Chinese railway standard, TEDRAIL also could offer customer qualified casting steel wheel center per following specifications:

- TB/T 1400 Techncial specification for cast steel wheel core for railway locomotive

Features:

- Material: ZG230-450, AAR M201 GRADE B, GRADE B+, GRADE C

- Machining: Wheel Center Hub and Rim is machined. Web is left for casting area.

- Test Certificate: Chemical Analysis, Tensile Test, Sectional Checking, Magnetic Particle Inspection, Dimension and Surface Checking.

- Heat Treatment Delivery Status: Normalized or Normalized and Tempered.