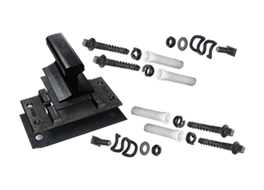

Some rails are joined together by welding, but most rails are connected by means of a pair of bolted fishplates. A fishplate, as well as called Rail Joint, Joint Bar, Splice Bar or Angle Bar is a metal bar that is bolted to the ends of two rails to join them together in a track.

TEDRAIL could supply most type of fishplates by hot-rolled, forged, and casted according to international railway fastener system such as:

- TB/T 2345

- UIC 864-4,UIC864-8,

- DIN 5902

- JIS E-1102

- AREMA,A.S.C.E,A.R.A

- BS 47-1

UIC 864-4,864-8 FISHPLATE

| Rail type | Fish plate type | Hole size (mm) | Length (mm) | H (mm) | G (mm) | F (mm) | C (mm) | MASS/PAIR (kg) | ||

| 4-Hole | 6-Hole | 4-Hole | 6-Hole | |||||||

| UIC54 | U79 | 27 | 660 | 920 | 127 | 211 | 130 | 56.5 | 15.6 | 21.7 |

| UIC60 | U85 | 27 | 610 | 940 | 130 | 165 | 165 | 75 | 17.6 | 27.2 |

Material:

| Material | Chemical Composition(%) | Mechanical Property | |||||

| C | Si | Mn | P | S | Tensile Strength | Elongation | |

GB/T 699-2008 40#,45# Carbon Steel | 0.27 ~ 0.48 | ≤0.38 | ≤0.94 | ≤0.058 | ≤0.058 | 550-650MPa | ≥18% |

| GB/T 1591 Q345 | ≤0.20 | ≤0.55 | 1.00~1.6 | ≤0.045 | ≤0.045 | 450-570MPa | ≥20% |

BS 47-1 FISHPLATE

| Rail type | Hole size (mm) | Length (mm) | H (mm) | G (mm) | F (mm) | Mass/pair (kg) | ||

| 4-Hole | 6-Hole | 4-Hole | 6-Hole | |||||

| 50 “O” | 20.64 | 406.4 | 609.6 | 101.6 | 101.6 | 101.6 | 6.68 | 10.14 |

| 60 A | 20.64 | 406.4 | 609.6 | 101.6 | 101.6 | 101.6 | 9.84 | 14.76 |

| 60 R | 20.64 | 406.4 | 609.6 | 101.6 | 101.6 | 101.6 | 8.75 | 13.14 |

| 70 A | 23.81 | 406.4 | 609.6 | 101.6 | 101.6 | 101.6 | 11.10 | 16.65 |

| 75 A | 23.81 | 406.4 | 609.6 | 101.6 | 101.6 | 101.6 | 11.82 | 17.73 |

| 80 A | 23.81 | 406.4 | 609.6 | 101.6 | 101.6 | 101.6 | 13.15 | 19.72 |

| 80 R | 23.81 | 406.4 | 609.6 | 101.6 | 101.6 | 101.6 | 11.92 | 17.89 |

| 80 “O” | 23.81 | 508.0 | 767.0 | 127 | 127 | 127 | 14.72 | 22.69 |

| 90 A | 26.99 | 457.2 | 685.8 | 114.3 | 114.3 | 114.3 | 17.49 | 26.23 |

| 90 R | 26.99 | 457.2 | 685.8 | 114.3 | 114.3 | 114.3 | 15.72 | 23.58 |

| 95 A | 26.99 | 457.2 | 685.8 | 114.3 | 114.3 | 114.3 | 18.71 | 28.05 |

| 95 R | 26.99 | 457.2 | 685.8 | 114.3 | 114.3 | 114.3 | 16.42 | 24.63 |

| 100 A | 26.99 | 457.2 | 685.8 | 114.3 | 114.3 | 114.3 | 19.96 | 29.94 |

| 110 A | 26.99 | 508 | 914.4 | 127 | 127 | 203.2 | 30.14 | 54.70 |

| 113 A | 27.0 | 507 | 914.0 | 127 | 127 | 203 | 30.11 | 54.64 |

Material:

| Material | Chemical Composition | Mechanical Property | |||||

| GB/T 699-2008 | C | Si | Mn | P | S | Tensile Strength | Elongation |

| 40#,45# Carbon Steel | 0.27 ~ 0.48 | ≤0.38 | ≤0.94 | ≤0.058 | ≤0.058 | 550-650Mpa | ≥18% |

AREMA,ASCE,ARA–JOINT BAR

There are three types of standard joint bars which are currently in service for AREMA, ASCE, ARA, AREA standard rail system. The charts below show the type of bar which is supplied for each rail section.

- Splice Bar

- Full Toe Angle Bar

- Short Toe Joint Bar

Joint bars must be punched to match rail drilling accurately to insure proper rail alignment. An additional chart show standard rail drilling and joint bar punching. There are two type of standard bar punching, four-hole joint bar and six-hole joint bar. Six-hole joint bars are provided for all crane rails and new tee rail sections over l00-lb peryard. New rail100-lb per yard and less is furnished with four-hole joint bars.

| Rail type | Common type | Length (inch) | H(inch) | G(inch) | F(inch) | Mass/pair (lbs) | |

| 4-hole | 6-hole | ||||||

| ASCE 25 | Splice Bar | 16-1/8 | 4-1/8 | 4 | 4 | 4.5 | - |

| ASCE 30 | Splice Bar | 16-1/8 | 4-1/8 | 4 | 4 | 7.0 | - |

| ASCE 40 | Splice Bar | 20 | 5-1/8 | 5 | 5 | 12.0 | - |

| ASCE 60 | Angle Bar | 20 | 5-1/8 | 5 | 5 | 27.2 | - |

| ASCE 80 | Angle Bar | 24 | 5-1/8 | 5 | 5 | 46.0 | - |

| ASCE 85 | Angle Bar | 24 | 5-1/8 | 5 | 5 | 47.3 | - |

| ARA-A 100 | Angle Bar | 22/33 | 5-1/2 | 5-1/2 | 5-1/2 | 53.5 | 80.3 |

| AREA 100 | Angle Bar | 22 | 5-1/2 | 5-1/2 | 5-1/2 | 51.9 | - |

| AREA 115 | Angle Bar | 25/36 | 7-1/8 | 6 | 6 | 69.4 | 99.8 |

| AREA 132 | Angle Bar | 24/36 | 7-1/8 | 6 | 6 | 71.0 | 103.5 |

| AREA 136 | Angle Bar | 24/36 | 7-1/8 | 6 | 6 | 71.0 | 103.5 |

| 104 LB CR | Angle Bar | 34 | 7-15/16 | 5 | 6 | - | 60.2 |

| 105 LB CR | Splice Bar | 34 | 7-15/16 | 5 | 6 | - | 51.6 |

| 135 LB CR | Splice Bar | 34 | 7-15/16 | 5 | 6 | - | 57.8 |

| 171 LB CR | Splice Bar | 34 | 7-15/16 | 5 | 6 | - | 72.1 |

| 175 LB CR | Splice Bar | 34 | 7-15/16 | 5 | 6 | - | 69.4 |

DIN 5902 FISH PLATES

| Type | Rail type | Length (mm) | A (mm) | B (mm) | C (mm) | Mass/piece (kg) |

| FL 7 | S 7 | 280 | 70 | 70 | 35 | 1,19 |

| FL 10 | S 10 | 300 | 75 | 75 | 37,5 | 1,36 |

| FL 14 | S 14 | 330 | 75 | 90 | 37,5 | 2,6 |

| FL 18 | S 18 | 330 | 75 | 90 | 37,5 | 3,1 |

| FL 20 | S 20 | 330 | 75 | 90 | 37,5 | 3,2 |

| FL 30 | S 30 | 530 | 128,6 | 127 | 73,7 | 9,5 |

| FL 33 | S 33 | 530 | 130 | 120 | 80 | 12,69 |

| FL 41/49 | S 41 / S 49 | 580 | 100 | 165 | 75 | 17,44 |

| FL 14a | S 49 / S 54 | 630 | 100 | 165 | 10 | 25,52 |

| FL 54E1 | 54E1 UIC54 | 670 | 130 | 200 | 70 | 30,40 |

| FL 46E3 | 46E3 NP46 | 700 | 130 | 200 | 85 | 12,40 |

Material:

| Material | Chemical Composition (%) | Mechanical Property | ||||||

| GB/T 700-2008 | C | Si | Mn | P | S | Tensile Strength | Yield Strength | Elongation |

| Q235B | ≤0.20 | ≤0.35 | ≤1.4 | ≤0.035 | ≤0.035 | ≥375 MPa | ≥235 MPa | ≥21% |

CHINESE STANDARD JOINT BAR

| CHINESE STANDARD JOINT BAR | ||

| SIZE | STANDARD | MATERIAL |

| 43KG | TB/T 2345-2008 | 55# |

| 50KG | ||

| 60KG | ||

| 75KG | ||

Standard:

TB/T 2345-2008

Material:

Chinese steel grade 55#

ChemicalComposition

| C | Mn | Si | S | P |

| 0.52-0.6 | 0.5-0.8 | 0.17-0.37 | ≤0.035 | ≤0.035 |

MechanicalProperty

- TensilestrengthRm:≥785Mpa

- Yield strength Rel / Rr0.2 : ≥520 Mpa ElongationA:≥9

- Reduction of Area Z: ≥20%

- Cold Bend d=3a: 30 degree, no crack

Hardness:

Hardness HBW: HBW 227-388

![1446615719746945.png ].png](/application/views/uploads/Product/1446615719746945.png)