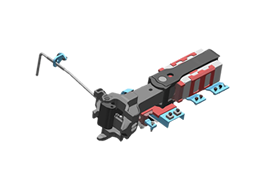

SASKOP TYPE COUPLER

SASKOP coupler, is a kind of Knuckle coupler, includes “SS”,”MS” and “HS” types which are widely used on African, such as South Africa, Botswana, Tanzania, Zambia.

Tedrail have the ability to supply “SS” and “MS” type couplers which manufactured according to AAR M-211 specification.

Parts Number

Coupler assembly:CME 68/10718-478

Coupler Body:&CME68/14456-993

Coupler Knuckle:&CME68/16194-641

Coupler Lock:nbsp;CME68/17708-751

Lifter:nbsp;nbsp;CME68/16695-717

Side Lever:nbsp;nbsp;CME68/16509-362

Pin-Knuckle:nbsp;nbsp;CME68/19793-431

Pin-Lock:nbsp;nbsp;CME68/19791-431

Pin Side Lever:CME68/19866-431

Casting Material:

Material of type coupler body, knuckle and locks are AAR M-201 Grade C Steel per standard supplying condition, or AAR M-201 Grade E Steel which are casted by alloy steel and heated treated as quenching and tempering. Letter “C” or “E” will be casted on the product body indicates the material Grade.&

Variation of Type SASKOP Coupler

According to the wagon application, SASKOP coupler could be supplied as following types:

SS Coupler

MS coupler

HS coupler

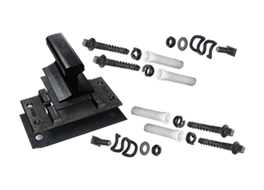

Connection Parts

Yoke:nbsp;CME68/31956-467

Yoke Key:nbsp;CME68/10534-488

Follower:nbsp;CME68/02891-704

Couplernbsp;Guide: CME68/13215-603

E/F TYPE COUPLER

E/F coupler is developed from Type E coupler, which has the same coupler head design with “E” Coupler, and same coupler shank and butt end design with type “F” coupler.

Variation of Type E/F Coupler

Like type “E” coupler and “F” coupler, according to wagon requirement, based on basic designed of “E” head and “F” shank, “E/F” couplers could have various compatible designs. Such as coupler head shelved, and extended the shank length, have been adopted in many applications.

Casting Material:

Material of type “E/F” coupler body, knuckle and locks are AAR M-201 Grade E Steel which are casted by alloy steel and heated treated as quenching and tempering. Letter “E” will be casted on the product body indicates the material Grade “E”. There also have the case required more strong material as AAR M-201 Grade E+. Using Grade E+ for coupler body and coupler knuckle will improve the coupler material tensile strength.

Interchangeability

All variation of type E/F coupler should be interchangeable, and have the No. 10-A contour at coupler mating lines. Coupler Contour should meet the requirement of AAR

S-106 specification same as type “E”.

Coupler Operating:

Single Rotary Bottom Operation

Double Rotary Bottom Operation

Top Operation

Connection Parts

Yoke:Y40AE – AAR S-141Y41AE – AAR S-142SY40AE - AAR S-143

Follower:Y46AE

Yoke Key:DRAFT KEY – AAR S-121

F TYPE COUPLER

Type F Featured as interlocking coupler is equipped with the F design head, the F design shank and butt end. It has a higher tensile strength than Type E couplers and has larger knuckles. They are bottom shelved and can have a top shelf as well. They can be identified by the interlocking feature to prevent couplers from disengaging during a derailment, improved from Type E and E/F design.

Several features are added include followings:

Less small contour slack and control of vertical interface movements reduced the wear of the coupler head surfaces, extending the knuckle service life. F coupler has only 3/8 inches of contour slack when linked by two new couplers, compared with the Type E and Type E/F as 25/32 inches, it will result in the improvement of the vertical dynamic mechanical performance of coupler, reduction of the vertical impact of two couplers and extension of the working life of wagon and its parts.

Improved the performance of wagon when running at the curved rail track and automatic center alignment. Using the shank butt alignment shoulders assist in keeping the coupler centered and car aligned automatically under heavy duty load when running at the curved rail track.

Vertical round pin connection and spherical butt end will make more convenient for assembly than the E coupler Cross Key structure, and also improve the running performance at curved rail track.

More reliable lock lift mechanism: two types of anti-jumping function integrated in the lock lift will keep the coupler locked securely.

Frontal interlocking mechanism at the coupler head can improve the coupling strength, and protect the knuckle and transmit the force to assist in dumping the wagon.

Frontal bottom support shelf is preventing happen of disconnecting of coupler from falling to the railroad and thereby becoming a serious derailment accident.

Variation of Type F Coupler

To meet varied wagon requirement, Type F couplers may be equipped with variant coupler shank designs and special features.

| Coupler Assembly | Parts | ||||||||||

| Body | Knuckle | Lock | Thrower | Knuckle Pin | Rotary locklift | Single Rotor | Double Rotor | Top locklift | Shelf & Shank | ||

| F70DE | Single | F70DE | F51AE | F41AE | F31 | C10&C11 | F7 | F8A | 17" shank | ||

| Double | F70DE | F51AE | F41AE | F31 | C10&C11 | F7 | F12 | 17" shank | |||

| Top | F70DE | F51AE | F41AE | F31 | C10&C11 | E6A | 17" shank | ||||

| SF70DE | Single | SF70DE | F51AE | F41AE | F31 | C10&C11 | F7 | F8A | 17 1/4" shank, Top Shelf | ||

| Double | SF70DE | F51AE | F41AE | F31 | C10&C11 | F7 | F12 | 17 1/4" shank, Top Shelf | |||

| F73BE | Single | F73BE | F51AE | F41AE | F31 | C10&C11 | F7 | F8A | 48" shank | ||

| Double | F73BE | F51AE | F41AE | F31 | C10&C11 | F7 | F12 | 48" shank | |||

| F79DE | Single | F73BE | F51AE | F41AE | F31 | C10&C11 | F7 | F8A | 48" shank | ||

| Double | F73BE | F51AE | F41AE | F31 | C10&C11 | F7 | 48" shank | ||||

| SF79DE | Single | SF70DE | F51AE | F41AE | F31 | C10&C11 | F7 | F8A | 31" shank, Top shelf | ||

| Double | SF70DE | F51AE | F41AE | F31 | C10&C11 | F7 | 31"shank, Top shelf | ||||

Casting Material:

Material of type F coupler body, knuckle and locks are AAR M-201 Grade E steel, which are casted by alloy steel and heated treated as quenching and tempering. Letter E will be casted on the product body indicates the material AAR Grade E. There also have the case required more strong material as AAR M-201 Grade E+. Using Grade E+ for coupler body and coupler knuckle will improve the coupler material tensile strength.

Interchangeability

All variation of type F coupler should be interchangeable, and have the No. 10-A contour at coupler mating lines. Coupler Contour should meet the requirement of AAR

S-117 specification.

Coupler Operating:

Single Rotary Bottom Operating

Double Rotary Bottom Operation

Top Operating

Unless specified on the order, F coupler will be fitted as Single Rotary Bottom Operating type.

Connection Parts

Yoke: Y45AE – AAR S-149

Follower: Y46AE

Yoke Pin: Y47 – AAR M-118

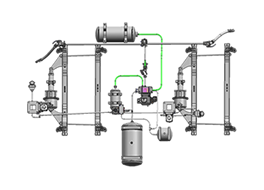

F ROTARY TYPE COUPLER

As for the heavy haul coal service, Tedrail supply the F type Rotary Couplers which could together working with F type fixed coupler for dumping application.

Type of F Rotary Coupler

AAR standard FR209E type and Chinese Standard FCR16 type could be supplied.

Casting Material:

Material of type F rotary coupler body, knuckle and locks are AAR M-201 Grade E steel, which are casted by alloy steel and heated treated as quenching and tempering. Letter E will be casted on the product body indicates the material AAR Grade E. There also have the case required more strong material as AAR M-201 Grade E+. Using Grade E+ for coupler body and coupler knuckle will improve the coupler material tensile strength.

Interchangeability

Type “F” rotary coupler should be interchangeable with type F coupler. Production and specification should meet the requirement of AAR specification used for type F coupler.

Connection Parts

Yoke: Y45AE – AAR S-149

Follower: Y46AE

Yoke Pin: Y47 – AAR M-118

Rotating sleeve

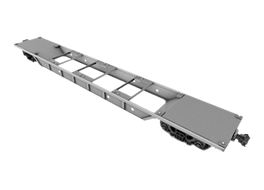

E TYPE COUPLER

The Type E coupler, designed in 1932, does not interlock in the vertical direction. While closed Type E couplers will separate only in the most extreme circumstances. This lack of a vertical interlock led to development of Type E shelf couplers and Type F and H couplers. Using varying "locking" features (e.g., top and bottom shelves and machined inter lockings), these more intricate couplers in most cases will prevent disengagement during a derailment, reducing the chances of a train jackknifing, or cars puncturing each other.

Variation of Type E Coupler

All E couplers have a basic “E” coupler head design and coupler tail with the flat hole fixed with Yoke by Draft Key. Such as E60DE, the couple is standard E design for AAR. According to customer requirement, Tedrail could supply a lot of variation of E coupler, such as with Bottom Shelf, Top Shelf or Double Shelf. And also according to the application, the coupler shank length could be adapted.

Casting Material:

Material of type E coupler body, knuckle and locks are AAR M-201 Grade C steel or AAR M-201 Grade E Steel which are casted by alloy steel and heated treated as quenching and tempering. Letter “C” or “E” will be casted on the product body indicates the material Grade. There also have the case required more strong material as AAR M-201 Grade E+. Using Grade E+ for coupler body and coupler knuckle will improve the coupler material tensile strength.

Interchangeability

All variation of type E coupler should be interchangeable, and have the No. 10-A contour at coupler mating lines. Coupler Contour should meet the requirement of AAR S-106 specification.

Coupler Operating:

- Single Rotary Bottom Operation

- Double Rotary Bottom Operation

- Top Operation

Unless specified on the order, E coupler will be fitted as Single Rotary Bottom Operating type.

Connection Parts

- Yoke:

- Y40AE – AAR S-141

- Y41AE – AAR S-142

- SY40AE - AAR S-143

- Follower:

- Y44A – AAR S-119

- Yoke Key:

- DRAFT KEY – AAR S-121

| Coupler complete1111 | Parts | ||||||||||

| Body | Knuckle | Lock | Thrower | Knuckle pin | Single locklift | Double locklift | Top locklift | Type | Shelf & shank type | ||

| E60DE | Singe rotary | E60DE | E50AE/E50ARE | E42AE | E30A | C10&C11 | E24B | E | 21.5”shank | ||

| Double rotary | E60DE | E50AE/E50ARE | E42AE | E30A | C10&C11 | E25B | E | 21.5”shank | |||

| Optional top | E60DE | E50AE/E50ARE | E42AE | E30A | C10&C11 | E6A | E | 21.5”shank | |||

| E60EE | Singe rotary | E60EE | E50AE | E40AE | E30A | C12&C13 | E24B | E | 21.5”shank | ||

| Double rotary | E60EE | E50AE | E40AE | E30A | C12&C13 | E25B | E | 21.5”shank | |||

| SE60DE | Rotary | SE60DE | E50AE/E50ARE | E42AE | E30A | C10&C11 | E24B | E | 21.5”shank | ||

| Optional top | SE60DE | E50AE/E50ARE | E40AE | E30A | C10&C11 | E6A | E | 21.5”shank | |||

| SE60EE | Rotary | SE60EE | E50BE | E42BE | E30A | C12&C13 | E24B | E | 21.5”shank | ||

| E67CE | Singe rotary | E67CE | E50AE/E50ARE | E40AE | E30A | C10&C11 | E24B | E | 25”shank | ||

| Double rotary | E67CE | E50AE/E50ARE | E40AE | E30A | C10&C11 | E25B | E | ||||

| Optional top | E67CE | E50AE/E50ARE | E40AR | E30A | C10&C11 | E6A | E | ||||

| E67DE | Singe rotary | E67DE | E50BE | E42BE | E30A | C12&C13 | E24B | E | 25”shank | ||

| Double rotary | E67DE | E50BE | E42BE | E30A | C12&C13 | E25B | E | 25”shank | |||

| E68CE | Singe rotary | E68CE | E50AE/E50ARE | E42AE | E30A | C10&C11 | E24B | E/F | 31”shank | ||

| Double rotary | E68CE | E50AE/E50ARE | E42AE | E30A | C10&C11 | E25B | E/F | 31”shank | |||

| E68EE | Singe rotary | E68EE | E50BE | E42BE | E30A | C12&C13 | E24B | E/F | 31”shank | ||

| Double rotary | E68EE | E50BE | E42BE | E30A | C12&C13 | E25B | E/F | 31”shank | |||

| E69BE | Singe rotary | E69BE | E50AE/E50ARE | E42AE | E30A | C10&C11 | E24B | E/F | 48”shank | ||

| Double rotary | E69BE | E50AE/E50ARE | E42AE | E30A | C10&C11 | E25B | E/F | 48”shank | |||

| E69CE | Singe rotary | E69CE | E50BE | E42BE | E30A | C12&C13 | E24B | E/F | 48”shank | ||

| Double rotary | E69CE | E50BE | E42BE | E30A | C12&C13 | E25B | E/F | 48”shank | |||

| SE67CE | Rotary | SE67CE | E50AE/E50ARE | E42AE | E30A | C10&C11 | E24B | E | 25”shank | ||

| Optional top | SE67CE | E50AE/E50ARE | E40AE | E30A | C10&C11 | E6A | E | 25”shank | |||

| SE67DE | Rotary | SE67DE | E50BE | E42BE | E30A | C12&C13 | E24B | E | 25”shank | ||

| SE68CE | Rotary | SE68CE | E50AE/E50ARE | E42AE | E30A | C10&C11 | E24B | E/F | 31”shank | ||

| SE68DE | Rotary | SE68DE | E50BE | E42BE | E30A | C12&C13 | E24B | E/F | 31”shank | ||

| SBE60DE | Rotary | SBE60DE | E50AE/E50ARE | E42AE | E30A | C10&C11 | E24B | E | 21.5”shank | ||

| Optional top | SBE60DE | E50AE/E50ARE | E40AE | E30A | C10&C11 | E6A | E | 21.5”shank | |||

| SBE60EE | Rotary | SBE60EE | E50BE | E42BE | E30A | C12&C13 | E24B | ||||

| SBE67CE | Rotary | SBE67CE | E50AE/E50ARE | E42AE | E30A | C10&C11 | E24B | E | 25”shank | ||

| Optional top | SBE67CE | E50AE/E50ARE | E40AE | E30A | C10&C11 | E6A | E | 25”shank | |||

| SBE67DE | Rotary | SBE67DE | E50BE | E42BE | E30A | C12&C13 | E24B | E | 25”shank | ||

| SBE68CE | Rotary | SBE68CE | E50AE/E50ARE | E42AE | E30A | C10&C11 | E24B | E | 31”shank | ||

| SBE68DE | Rotary | SBE68DE | E50BE | E42BE | E30A | C12&C13 | E24B | E/F | 31”shank | ||

| SBE69BE | Rotary | SBE69CE | E50AE/E50ARE | E42AE | E30A | C10&C11 | E24B | E/F | 31”shank | ||

| SBE69CE | Rotary | SBE69DE | E50BE | E42BE | E30A | C12&C13 | E24B | E/F | 48”shank | ||

| SE69BE | Rotary | SE69CE | E50AE/E50ARE | E42AE | E30A | C10&C11 | E24B | E/F | 48”shank | ||

| SE69CE | Rotary | SE69DE | E50BE | E42BE | E30A | C12&C13 | E24B | E/F | 48”shank | ||