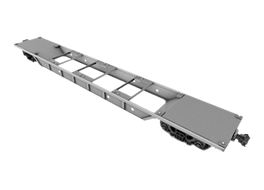

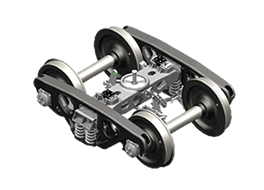

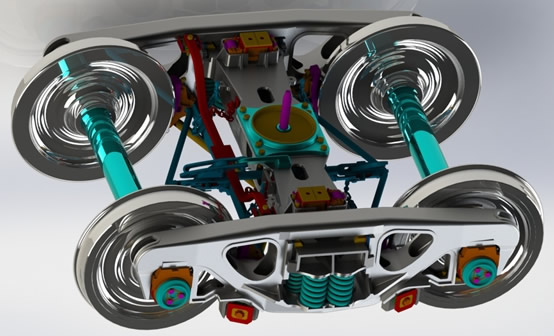

ABogieas well as called Truck American is achassisor framework carrying wheels, attached to a vehicle, thus serving as amodular subassembly of wheels andaxles.

Bogies serve a number of purposes:

Support of the rail vehicle body.

Stability on both straight and curved track.

Ensuring ride comfort by absorbing vibration and minimizing the impact of centrifugal forces when the train runs on curves at high speed.

Minimizing generation of track irregularities and rail abrasion

Key components of a bogie include:

The bogie frame: This can be of inside frame type where the main frame and bearings are between the wheels, or (more commonly) of outside frame type where the main frame and bearings are outside the wheels.

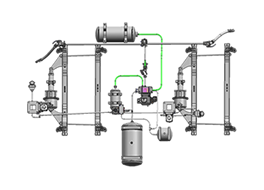

Suspensionto absorb shocks between the bogie frame and the rail vehicle body: Common types arecoil springs, or rubber airbags.

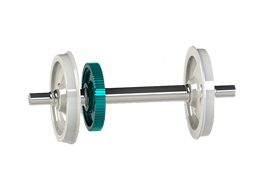

At least onewheelset, composed of anaxlewithbearingsand awheelat each end

Axle box suspensions absorb shocks between the axle bearings and the bogie frame. The axle box suspension usually consists of a spring between the bogie frame and axle bearings to permit up-and-down movement, and sliders to prevent lateral movement. A more modern design uses solid rubber springs.

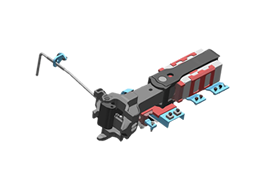

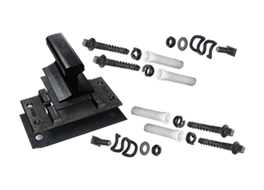

Brake equipment: Two main types are used:brake shoesthat are pressed against the tread of the wheel, anddisc brakesand pads.

In powered vehicles, some form oftransmission, usually electrically poweredtraction motorsor a hydraulically poweredtorque converter

Tedrail Supply the most type of freight wagon bogies according to following features:

Bogie Type: Fabricate Type, Ride Control Type

Gauge:

Meter Gauge, 1000mm

Narrow Gauge, 1067mm

Standard Gauge 1435mm

Broad Gauge 1520mm, 1676mm

Wheel Diameter:

28” (711mm), 30” (762mm),33” (840mm),36” (920mm)

Wheel Type:

Casting wheel, Forging wheel, Tyred wheel

Bogie basic parameter reference table

| Item | Axle load/T | Load /T | Optional wheelbase/mm | Bogie controllable weight/T tolerance±0.3T | ||||

| 1000 | 1067 | 1435 | 1520 | 1676 | ||||

| Number | 14 | 45 | | |  |  |  | 2.5-4 |

| 16 | 50 | | | |  |  | 3-4.5 | |

| 20 | 60 | | | | | | &3.5-5 | |

| 25 | 78 | | | | | | 4-5.5 | |

| 30 | 95 |  | | | | | 4.5-6 | |

| 32.5 | 100 |  |  | | | | 4.5-6.5 | |

| Optional type of axle:AAR C/D/E/F/G grade shaft/bearing Wheel:rolled steel,cast steel | ||||||||

| Brake optional type:Mechanical lever type basic brake / unit brake | ||||||||

| Optional operating speed:60~160KM/H | ||||||||

| Bound: can be designed according to different clearance requirements, matching | ||||||||

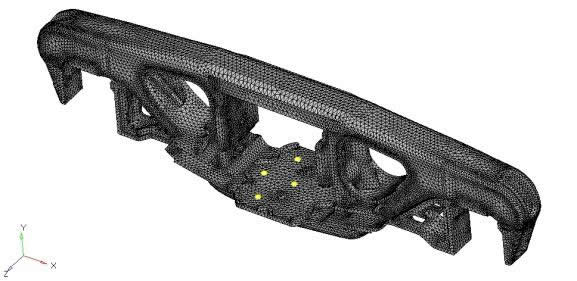

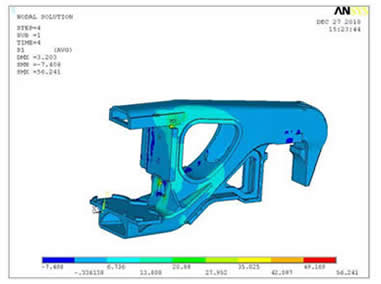

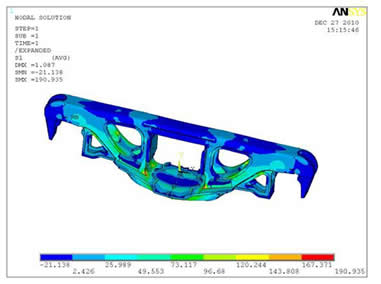

Design and Validation

Tedrail have the ability to design the new bogies according to customer application, have our design and validation of process to guarantee the reliability as followings:

Prototype Design according to indicated parameters from customer requirement.

Structure Design after prototype design has been approved by customer

FEA (Finite Element Analysis) for Fatigue Life of Bogie Frame

Static Strength and Dynamic Strength Testing for Bogie Frame

Bogie Running Tests

1435

axle load:20T

speed:100-160km/h

- gauge:

1435

axle load:20T

speed:100-160km/h

Covered wagon Hopper car - gauge:

1435/1676

axle load:25T/30T

speed:120-160km/h

Hopper car Covered wagon Gondola car Flat car Tank car - gauge:

1067

axle load:20T

speed:80-160km/h

Hopper car Covered wagon Gondola car Flat car Tank car - gauge:

1435/1676

axle load:20T/25T

speed:120-160km/h

Hopper car Covered wagon